Carbon fiber does it better

Why should you swap tried and tested materials such as stainless steel for carbon fiber reinforced plastic (CFRP)? Quite simply: because it is low-particle, chemical-resistant, unbreakable and—unlike stainless steel—ultra-light. This makes carbon fiber reinforced plastic (CFRP) the ideal material for mop frames and handles in cleanroom cleaning.

From outer space to the cleanroom

Carbon fiber reinforced plastics were originally developed as lightweight materials for space travel. Their advantages - stability, flexibility and lightness - were quickly discovered for other areas of application. This is how carbon fiber made its way into motor racing... and cleanroom cleaning.

CFRP in cleanroom cleaning

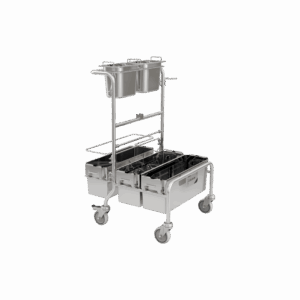

The low weight of the material makes it possible to break up traditional designs and create something new. This is what happened with the carbon fiber mop systems and isolator cleaning tools of the PurMop BLACK® Performance Line. New size, more features and more user-friendliness—carbon fiber makes it possible.

Learn more about the Performance Line

Carbon fiber products and mops for cleanroom cleaning

The product has been successfully added to your enquiry basket

Carbon fiber in sterile areas

Our carbon fiber mop systems have been extensively tested for autoclaving, wipe disinfection and fumigation with hydrogen peroxide. All methods can be used without hesitation as long as the tested conditions are adhered to.

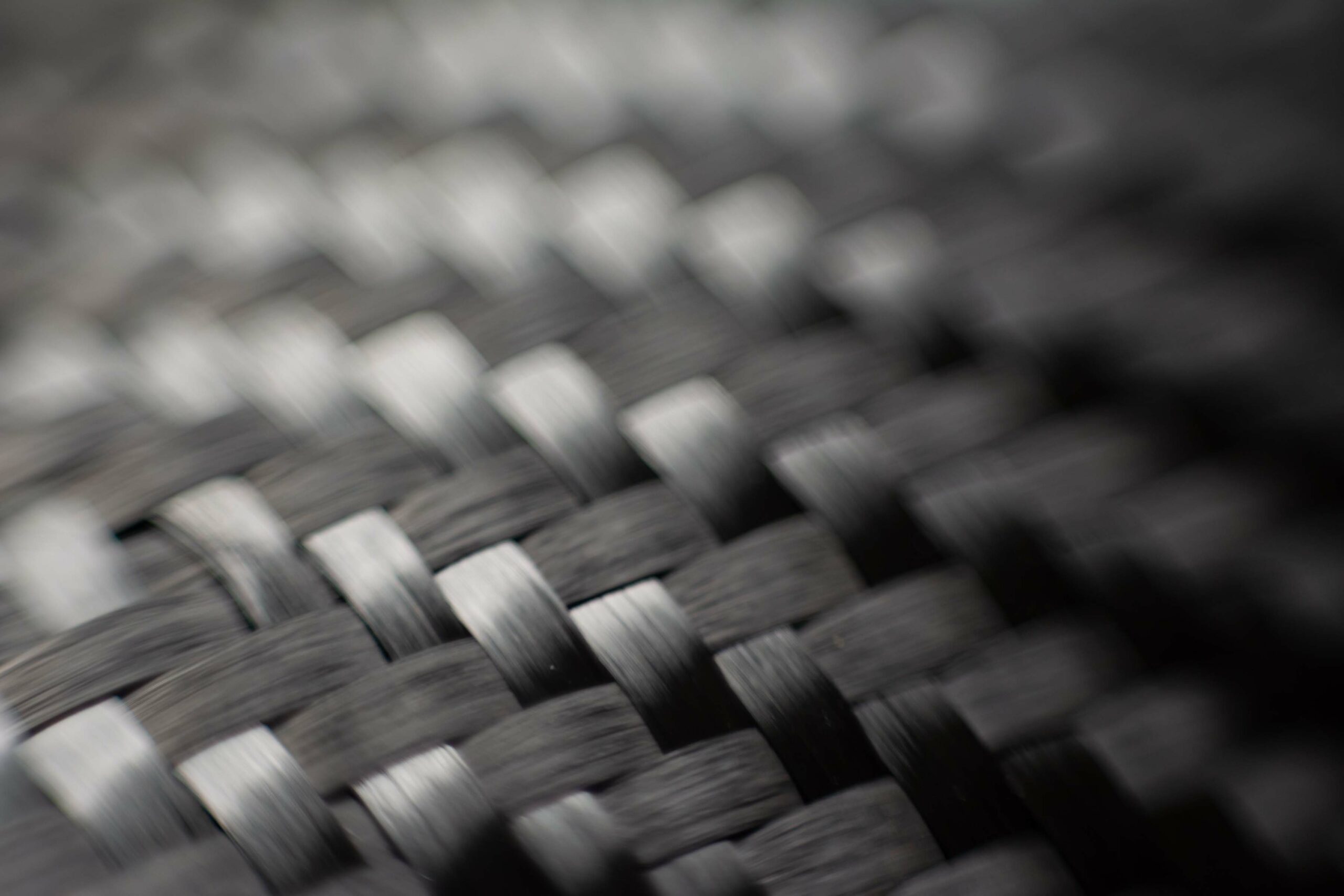

What is carbon fiber actually?

Carbon fiber is made from carbon filaments combined into strands. The structure and orientation of the fibers is responsible for their outstanding mechanical and physical properties. In order to make optimum use of the advantages of carbon fibers, they are embedded in a matrix of resins or thermoplastics. As a binder, the matrix regulates the force transmission between the fibers and distributes loads to surrounding fibers. It also protects against external influences.

Frequently asked questions

Is carbon fiber reinforced plastic suitable for cleanrooms?

Yes, it is suitable for cleanrooms. All products underwent extensive testing before they were launched on the market. They were in no way inferior to stainless steel products.

Is carbon fiber good for cleanroom cleaning?

It combines many advantages: It is lightweight, resistant to chemicals and can be permanently sterilized. This makes it the perfect material for cleanroom cleaning.

Which chemicals is carbon fiber reinforced plastic resistant to?

Carbon fiber reinforced plastic is resistant to common cleaning products. These include:

_ Diamines

_ Ethanol (70 %)

_ Isopropanol (70 %)

_ Phosphoric acid (8.5 %)

_ Sodium hydroxide (caustic soda)

_ Low residue peroxide

_ Hydrogen peroxide (11.9 %)

_ Sodium hypochlorite (12.5 %)

_ Active chlorine

_ Quart. Ammonium compounds (4 %)

Can carbon fiber reinforced plastic be sterilized?

All Hydroflex carbon fiber products are resistant to wipe disinfection, autoclaving and VPHP.

Are there any disadvantages if I use cabon fiber in the cleanroom?

There are no known disadvantages. Carbon fiber reinforced plastic has similar properties to stainless steel or aluminum, but with a significantly lower weight.

How long has carbon been used in cleanroom cleaning?

CFRP is a comparatively new material in cleanroom cleaning and has only been used for mop holders and handles for a few years. Already in this short time, it has proven its significant advantages.

For which cleanrooms is carbon suitable?

CFRP is suitable for all cleanroom classes in the GMP area and can be used up to ISO 5. Carbon fiber products can now also be found at leading companies in the pharmaceutical sector.

What makes carbon so special?

CFRP consists of carbon fibers embedded in a high-performance plastic (= matrix). This matrix is what makes the material so stable. The inspiration comes from nature: bones and bamboo canes use similar principles to ensure stability.